AW Process Specialist In The Cement Industry

C&W Environmental Solutions

C&W Environmental Solutions

C&W Environmental Solutions

C&W is the industry leader in environmental solutions. We can custom engineer environmental systems to meet your plants needs and requirements. You get the best technology available, including the latest in Bag-Pulse Jet, Cartridge Pulse, and Reverse Air with new designs on the horizon. Our Quality control division inspects every unit throughout our manufacturing process and factory tests each unit prior to shipping. We also have an extensive dealer network throughout the United States and numerous foreign countries.

Domtec Storage

C&W Environmental Solutions

C&W Environmental Solutions

Domtec is now a leading dome construction company with world-class bulk storage solutions in the mining, power, agriculture and cement industries. We have built domes on 5 continents, storing coal, wood pellets, fgd gypsum, fly ash, metals, ores, rare earth elements, potash, fertilizers, grains, peanuts, salt and sugar.

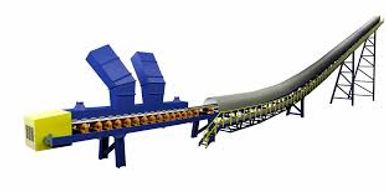

FEECO International

C&W Environmental Solutions

FEECO International

FEECO’s engineered bulk material handling equipment and systems are rugged, dependable, and built to last. Since 1951 FEECO has been designing and supplying bulk material handling systems for industries ranging from minerals and ores, to fertilizers and chemicals.

Bruks Siwertell

Ship Unloader

Siwertell port-mobile unloader

Siwertell port-mobile unloader

Siwertell ship unloaders are equipped with our unique inlet feeder that ensures efficient material pick-up into the vertical screw conveyor, providing consistently high unloading capacities. Conveyors are available in different sizes depending on cargo material and the capacity required.

Siwertell port-mobile unloader

Siwertell port-mobile unloader

Siwertell port-mobile unloader

They offer full port mobility, excellent efficiency and rated capacities and reduced investment costs.

Able to handle materials such as grain, soybean meal, alumina and cement, the port-mobile unloader has been optimized on many key levels from its stable, low weight steel structure through to its gentle cargo handling, smooth cargo discharge, and cost-efficient operation.

PEBCO

Dustless Loading Spouts

Telescopic Chute Ship Loading / Stockpiling

Telescopic Chute Ship Loading / Stockpiling

PEBCO Dustless Loading Spouts are the industry standard for reducing dust emissions. Industry standard for reducing emissions when loading trucks, trains, barges, or in stockpiling applications. Ideal for grains, cement, ash, sand, fertilizers, coal, lime, plastics, and many more. Standard sizes available for 200, 300, 450, and 720 CFM material flow rates. Travel ranges from 1' to 50'.

Telescopic Chute Ship Loading / Stockpiling

Telescopic Chute Ship Loading / Stockpiling

Telescopic Chute Ship Loading / Stockpiling

Pebco Telescopic Chutes are ideal for outdoor stockpiling or ship loading for their ability to contain product during freefall and accommodate a variety of application sizes and flow rates.

Copyright © 2020 aw process - All Rights Reserved.

Powered by GoDaddy